Products & Services for Semiconductors

Product Lineup

Thermocouple for High Temperature Furnace

Mainly structured with SiC protection tube, this product is used for diffusion furnaces and CVD equipments.

L-shaped Quartz Thermocouple

Mainly structured with quartz protection tube, this product is used for diffusion furnace sand CVD equipments.

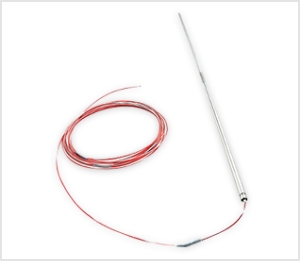

Spike Thermocouple

This product is used for controlling heater output (temperature) of diffusion furnace sand CVD equipments.

Quality Management Initiatives

Clean Room

Process from components storage to product manufacture are carried out in Class 5000 environment.

Thermocouple Calibrator

To accurately measure the temperature, this machine measures the error of thermoelectromotive force against the standard temperature.

Our Strengths

We are processors that handles PGM materials from raw materials. Effectively using this strength, we fabricate the metal wire and assemble the product. In addition, we recycle used thermocouple wire. After recycling, refining will be undertaken and the thermocouple will be returned to the customer. Utilizing the precious resource of PGMs at the maximum, we will respond to the customer’s requests.

Moreover, high purity quartz utilized in semiconductor segment are manufactured at our Chitose Plant.

We are recognized as “CERTIFIED APPROVED SUPPLIER for Thermo-couple Recast” in 2005 by Hitachi Kokusai Electric Inc.

Chitose Plant

At the Chitose Plant, we manufacture high-purity quartz protective tubes primarily used in thermocouples in the semiconductor field. Equipped with a clean room, the plant provides products which meet the specifications required in the semiconductor field. Moreover, the plant also handles quartz processing and repair in addition to protective tubes.

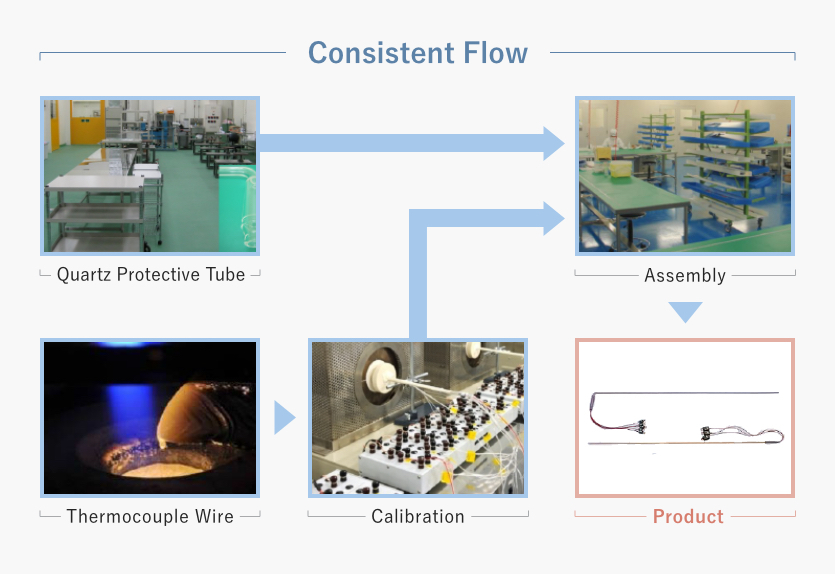

We integrated the manufacturing of everything from wire materials to quartz component processing and assembly to create high-quality products.

Characteristics of the Chitose Plant

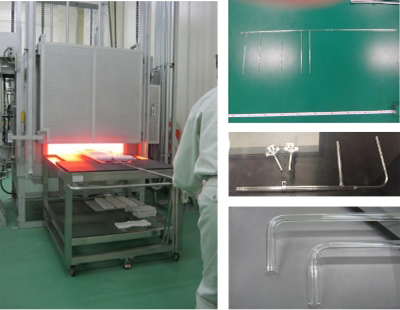

At the Chitose Plant, experienced engineers manufacture quartz protective tubes based on technical drawings. During the component treatment process, material cutting, polishing, and other primary processing for the quartz protective tubes is performed.

Bending, size adjustments, quartz protective tube edge sealing, parts welding, and other steps are performed in the heat treatment process. The mixing of impurities is eliminated by using a quartz nozzle burner to produce quartz products with high purity.

Products with less warping and other defects can be produced by using a large-sized furnace to perform the annealing step with the entire quartz protective tube inside the furnace.

Quartz Protective Tube Sample

The Chitose Plant cleaning process has cleaning tanks which are able to wash an entire protective tube. The cleaning process is managed by separating the cleaning tanks used for new and reconditioned products.

Quartz protective tubes manufactured at the Chitose Plant are inspected, dried, and packed in a Class 5000 environment.

CONTACT

Frequently asked questions.

- What is the maximum wafer size for film deposition?

- What is the annealing temperature?

- I'd like to reuse an used beet dish...

- I would like to know the price of Ru nitrate and the recent metal price.

Opening from 9:00 to 17:00 on weekdays