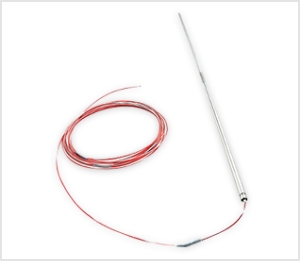

Reinforced Thermocouple Wire (R-SP)

Reinforced Thermocouple Wire (R-SP)

Increased Creep Strength Due to Change in T/C Manufacturing Method

Creep rupture can be named as a general disconnection mode for T/C.

Type R-SP T/C wire improves on the mode that disconnects due to creeps. This type R-SP T/C wire has improved creep strength without any additive material.

Disconnection Mechanism and Sectional Structure of the Wires

Wire Sectional Structure

Creep strength test / Drift test

Creep test Condition: 1100℃

Drift test

●Conventional RT/C 0Hr

■Conventional RT/C 2310Hr

●R-SP 0Hr

■R-SP 2310Hr

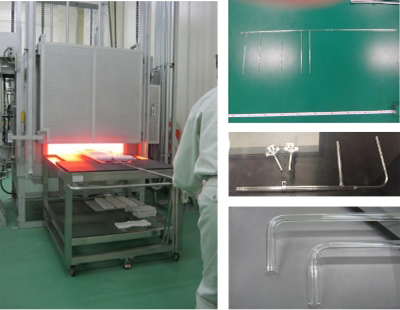

Heated Contact Point Utilizing Raw Materials

If a normal welding method is applied, the extended structure and the strengthened effect, which are characteristics of type R-SP wires, fade away. In order to combat this, welding is decreased, and it is possible to maintain the strength by wrapping and crimping a Pt sleeve around the wire.

Normal Welding

Boundary arises between the type R-SP structure and melted structure.

Crimp Junction

The extended structure, a unique characteristic of type R-SP, is maintained.

CONTACT

Frequently asked questions.

- What is the maximum wafer size for film deposition?

- What is the annealing temperature?

- I'd like to reuse an used beet dish...

- I would like to know the price of Ru nitrate and the recent metal price.

Opening from 9:00 to 17:00 on weekdays